Real talk: Cities are coffee capitals, and the competition is fierce. As specialty coffee demand surges in urban hubs, roasters are forced to rethink their strategies. High foot traffic, prime visibility, and proximity to customers make city centres lucrative—but they also demand ingenuity. With rental costs soaring and space shrinking, the future of coffee roasting lies in compact, smartly designed operations. The key? Turning constraints into advantages.

Smaller roasteries aren’t just a trend—they’re a necessity. Cities like Shanghai, Tokyo, and London boast thousands of coffee shops, creating a saturated market where differentiation is critical. For roasters like Lucas Hubinon and Nicolas Le Fourn of Celsius Roasters, the solution was to embrace tight spaces. “We wanted everything under one roof, as close as possible to our customers,” Lucas explains. Their Lyon-based roastery, designed with IMF Roasters, proves that compact doesn’t mean compromised. By prioritizing airflow, noise control, and storage efficiency, they’ve created a model others can replicate.

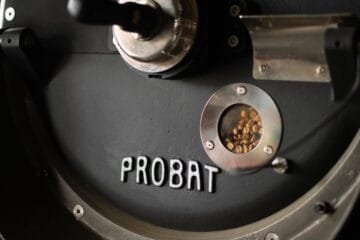

Urban roasting isn’t just about fitting equipment into a small space—it’s about solving complex problems. Ventilation, noise, and emissions regulations are non-negotiable, especially in densely populated areas. “You need a storage space for green coffee that’s stable, not subject to temperature swings,” Lucas notes. Meanwhile, deliveries in narrow streets require diplomacy and speed. IMF Roasters’ integrated systems, like the RM15 roaster, address these challenges. Its compact design and afterburners handle emissions without sacrificing floor space, while precision automation lets roasters focus on quality over troubleshooting.

The shift to urban roasting also means doubling as a café. This dual function demands equipment that’s both efficient and visually appealing. “Our roaster allows us to focus solely on batch improvement,” Lucas says. The RM15’s convection system minimizes waste, letting roasters experiment without fear of losing costly beans. For small operators, this balance of tech and design isn’t just practical—it’s transformative.

Opt for compact, integrated systems like the IMF RM15 to maximize efficiency.

Key points: Prioritize airflow and noise control to meet urban regulations. Opt for compact, integrated systems like the IMF RM15 to maximize efficiency. Balance production with customer-facing areas to turn space constraints into brand assets.

Close: Ever run a roastery in a tight space? How did you turn the challenge into an opportunity? Share your story below.

Questions & Answers

What equipment is needed for a compact coffee roastery?

Essential equipment includes a small roaster, grinders, storage containers, and packaging tools. Prioritize space-efficient models to fit limited areas without sacrificing quality or workflow.

How to minimize space in a coffee roastery?

Use multi-functional tools, stackable storage, and compact machinery. Optimize layout with vertical space and choose modular setups for flexibility and efficiency.

Information sourced from industry reports and news outlets.